[An earlier discussion about this boat focused on engine mounting height and possible changes and benefits.]

I did not change the engine mounting height for the Yamaha 90-HP two-stroke-power-cycle engine on my NAUSET 16 boat [as was discussed in the prior thread], and I left the engine as it had been mounted [in the lowest possible position and] using the blind mounting bolts.

With a Yamaha aluminum propeller [of unknown number of blades and] 17-pitch, the NAUSET 16 boat is very responsive. The Yamaha 90-HP engine accelerates at full throttle to 5,500-RPM, producing a boat speed of 42-MPH speed over ground by GPS.

I feel that less than 1-MPH speed would be gained if the engine were raised two-holes higher.

I feel that replacing the current aluminum propeller with a better propeller might add a bit more boat speed--but not very much.

Advice I got from Jim and Phil [who both recommended against buying and installing a jack plate] was good advice, and I saved a lot of time and money [by not buying and installing a jack plate].

The 50-year-old NAUSET 16 is shown in Figures 1, 2, and 3.

The original wooden components were taken apart, stripped, repaired, and put back together. To replace the original wood with new wooden parts would have been a lot less work, but the plywood available today is just not suited or intended for marine use.

NAUSET 16 Yamaha 90-HP

Re: NAUSET 16 Yamaha 90-HP

Getting a boat speed of 42-MPH sounds quite good to me for an old 16-footer and an aluminum propeller.

The boat looks very nice, too. Where is that dock?

The boat looks very nice, too. Where is that dock?

Re: NAUSET 16 Yamaha 90-HP

After reading your post and a good night sleep, I think you should upgrade the propeller to the Yamaha painted stainless steel model in 13 x 17.

It will not need to be replaced if you hit a buoy or debris.

The boat will perform better at all speeds.

Just be happy you don't need an Enertia propeller for $860--No foolin'.

It will not need to be replaced if you hit a buoy or debris.

The boat will perform better at all speeds.

Just be happy you don't need an Enertia propeller for $860--No foolin'.

1992 Outrage 17

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

2019 E-TEC 90

2018 LoadRite 18280096VT

Member since 2003

Re: NAUSET 16 Yamaha 90-HP

Again, Phil and I agree: an aluminum propeller has about zero tolerance for a blade striking anything, while a steel propeller will tolerate a blade strike with some sort of softer material without any deformation of the steel.

If you do any boating in shallow water, there will be some sort of encounter between a propeller blade and something in the water at some point in your future.

If you do any boating in shallow water, there will be some sort of encounter between a propeller blade and something in the water at some point in your future.

Re: NAUSET 16 Yamaha 90-HP

Dock is located on Winnapaug Pond in Westerly, Rhode Island. The pond is saltwater and tidal. The location is the west end, north shore. I built the dock 15 years ago. It is 100-feet long, as was needed to get some water depth. The photo from my front yard.

Re: NAUSET 16 Yamaha 90-HP

I am updating this two-year-old thread note update changes I have made.

I broke down and decided to fix the blind-hole mounting problem by installing a CMC 2-1/2-inch fixed jack plate, their part 65213.

The small CMC jack plate is a very easy method of using the old blind-fasterner mounting transom hole to attach the jack plate, and then using the new bolt pattern (on the jack plate) to mount the engine.

I now have the engine mounted-up 2-1/2-inches above the top of the transom. I switched to a Yamaha Performance Series, stainless steel, three-bladed 13-1/4-inch x 16-pitch propeller.

Top boats speed is now 44-MPH (measured by GPS receiver) at an engine speed of 5,500-RPM. The boat handling is better, the draft of the engine has been reduced, and the top speed has increased.

Using a jack plate was a good solution to this common problem [of mounting an engine on older boats with shallow engine splash wells where drilling the standard BIA lower mounting hole in the transom would be impractical because it would exit below the splash well on the inboard side of the transom]. I hope this [new information on the outcome of adding a jack plate to a NAUSET 16 will] help someone in the future.

I broke down and decided to fix the blind-hole mounting problem by installing a CMC 2-1/2-inch fixed jack plate, their part 65213.

The small CMC jack plate is a very easy method of using the old blind-fasterner mounting transom hole to attach the jack plate, and then using the new bolt pattern (on the jack plate) to mount the engine.

I now have the engine mounted-up 2-1/2-inches above the top of the transom. I switched to a Yamaha Performance Series, stainless steel, three-bladed 13-1/4-inch x 16-pitch propeller.

Top boats speed is now 44-MPH (measured by GPS receiver) at an engine speed of 5,500-RPM. The boat handling is better, the draft of the engine has been reduced, and the top speed has increased.

Using a jack plate was a good solution to this common problem [of mounting an engine on older boats with shallow engine splash wells where drilling the standard BIA lower mounting hole in the transom would be impractical because it would exit below the splash well on the inboard side of the transom]. I hope this [new information on the outcome of adding a jack plate to a NAUSET 16 will] help someone in the future.

Re: NAUSET 16 Yamaha 90-HP

Just to clarify a bit, the jack plate used is provided in two separate pieces as seen in Figure 5. Both the transom-side and engine-side have matching holes spaced with the BIA engine mounting standard. The engine bolts onto those BIA spaced holes, and you can adjust the vertical height by selecting one of the several sets of holes on the engine mounting bracket.

In mounting the jack plate to the existing transom of the NAUSET 16, I assume that the boat side of the jack plates were re-drilled with a new hole on each side that matches the lower mounting hole that was in the blind-fastener position on the existing tansom. The blind-fastener mounting hole is located slightly wider than the normal lower mounting holes as seen in Figure 5. Those new holes would need to be drilled accurately so they match the existing transom holes in the blind-fastener position.

By my math, the new blind-fastener holes are going to be 2-inches higher than the existing BIA lower hole and offset by 7/16-inch farther outboard from center. Of course, it may be better to use the actual transom and its existing lower holes as a template as long as you have the two-pieces of the jackplate bolted on to the upper holes and in excellent vertical alignment.

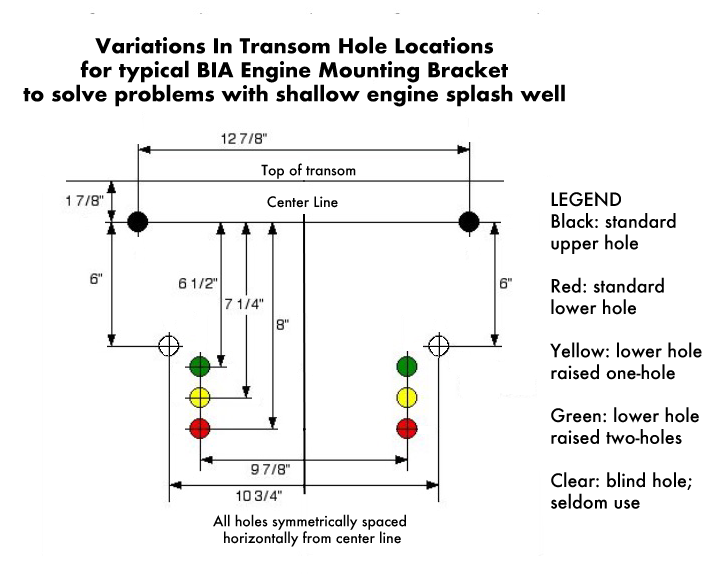

Fig. 6. The BIA transom hole layout. The blind fastener holes are the "clear" holes spaced 10-3/4-inches apart and 6-inches below the upper holes

CMC was formerly as separate company but has now become part of T-H Marine. The CMC jack plate part 65213 is made of 6061 Aluminum and has a MRSP of $179. At the T-H Marine website this particular product is currently listed as "unavailable."

On the engine-side mounting, it looks like there WILL NOT be much room between the two faces of the jack plate for the engine mounting bolts to be inserted with their heads facing the transom for both the lower and upper holes holes. The bolts for the upper and lower holes can be inserted on the boat side of the boat transom, with nuts on the jack plate interior face. For the engine, both upper and lower bolts will have to be inserted first through the engine mount with the threads toward the jack plate. The bolt length will have to carefully chosen to fit without interference in the space between the two faces of the jack plate.

Perhaps our author Blackduck can comment on how he mounted the jack plate to the hull and then the engine to the jack plate, or show us a good photograph that reveals the details.

In mounting the jack plate to the existing transom of the NAUSET 16, I assume that the boat side of the jack plates were re-drilled with a new hole on each side that matches the lower mounting hole that was in the blind-fastener position on the existing tansom. The blind-fastener mounting hole is located slightly wider than the normal lower mounting holes as seen in Figure 5. Those new holes would need to be drilled accurately so they match the existing transom holes in the blind-fastener position.

By my math, the new blind-fastener holes are going to be 2-inches higher than the existing BIA lower hole and offset by 7/16-inch farther outboard from center. Of course, it may be better to use the actual transom and its existing lower holes as a template as long as you have the two-pieces of the jackplate bolted on to the upper holes and in excellent vertical alignment.

Fig. 6. The BIA transom hole layout. The blind fastener holes are the "clear" holes spaced 10-3/4-inches apart and 6-inches below the upper holes

CMC was formerly as separate company but has now become part of T-H Marine. The CMC jack plate part 65213 is made of 6061 Aluminum and has a MRSP of $179. At the T-H Marine website this particular product is currently listed as "unavailable."

On the engine-side mounting, it looks like there WILL NOT be much room between the two faces of the jack plate for the engine mounting bolts to be inserted with their heads facing the transom for both the lower and upper holes holes. The bolts for the upper and lower holes can be inserted on the boat side of the boat transom, with nuts on the jack plate interior face. For the engine, both upper and lower bolts will have to be inserted first through the engine mount with the threads toward the jack plate. The bolt length will have to carefully chosen to fit without interference in the space between the two faces of the jack plate.

Perhaps our author Blackduck can comment on how he mounted the jack plate to the hull and then the engine to the jack plate, or show us a good photograph that reveals the details.

Re: NAUSET 16 Yamaha 90-HP

I will take a a picture or two this weekend to illustrate what I did with the brackets, and post them next week.

This method [of using a short set-back bracket] makes for a very neat upgrade and solution to a very common problem with older 16-foot hulls [with a shallow engine splash well].

I considered filling the blind-fastener hole and re-drilling [the transom], but I felt that [using a short set-back bracket] accomplished more.

Jimh did a good job in explaining the process.

Yes, the holes for using the existing blind-fastener locations had to be drilled in the new brackets.

And yes, there is very little room for installing the engine bolts themselves, but they will fit.

I put the bolt heads outboard on the top holes, no choice, and heads inboard on the bottom holes.

Also, I painted the unfinished aluminum brackets with Pettit Prop Coat to protect them from corrosion. The paint seems to be holding up well.

The work involved in the entire refit was relatively easy and straightforward.

This method [of using a short set-back bracket] makes for a very neat upgrade and solution to a very common problem with older 16-foot hulls [with a shallow engine splash well].

I considered filling the blind-fastener hole and re-drilling [the transom], but I felt that [using a short set-back bracket] accomplished more.

Jimh did a good job in explaining the process.

Yes, the holes for using the existing blind-fastener locations had to be drilled in the new brackets.

And yes, there is very little room for installing the engine bolts themselves, but they will fit.

I put the bolt heads outboard on the top holes, no choice, and heads inboard on the bottom holes.

Also, I painted the unfinished aluminum brackets with Pettit Prop Coat to protect them from corrosion. The paint seems to be holding up well.

The work involved in the entire refit was relatively easy and straightforward.

Re: NAUSET 16 Yamaha 90-HP

Figures 6, 7, and 8 show details of the mounting bolts.

Re: NAUSET 16 Yamaha 90-HP

The new illustrations at Figure 6,7, and 8 are very useful. They reveal the tight fit for the the upper mounting bolts due to their matching hole alignment. This alignment is avoided on the bottom bolts because the transom and engine holes are not aligned, a result of using the blind-fastener hole position on the transom. That actually is a bonus benefit for using the blind-fastener hole that was already in the transom.

I think readers can now really see the interesting details in mounting this bracket.

Let's hope CMC/T-H Marine continues to make this short set-back bracket, as they will be useful on many older 16-footers getting re-powered with modern engines.

I think readers can now really see the interesting details in mounting this bracket.

Let's hope CMC/T-H Marine continues to make this short set-back bracket, as they will be useful on many older 16-footers getting re-powered with modern engines.

Re: NAUSET 16 Yamaha 90-HP

[Moderator's note: In Figure 9 the lower bolts use are using the existing blind-fastener mounting bolt position already drilled in the transom from the original engine mounting, which was a skillful adaptation to the existence of those holes which were necessary because of the shallow engine splash well on the classic 16-foot hull. The set back bracket has been modified by drilling (in-situ) a matching hole in the aluminum bracket on the transom side of the bracket.]

Re: NAUSET 16 Yamaha 90-HP

Although the installation work was described above as being "relatively easy and straightforward," I think there are several potential problems that had to be overcome with the bolt lengths and proper location of the newly drilled holes in the set-back bracket, and our author blackduck is too modest. He solved several tricky problems on the way to a successful installation.

Overall the installation is a very nice accommodation for the shallow engine splash well problem on the classic 16-footer. And as a bonus the engine mounting height was increased two two-holes-up from lowest position, and the set-back bracked as added a few inches distance for the propeller to work from the transom. Both changes could possibly improve top boat speed performance. We await any new boat test speed results.

Overall the installation is a very nice accommodation for the shallow engine splash well problem on the classic 16-footer. And as a bonus the engine mounting height was increased two two-holes-up from lowest position, and the set-back bracked as added a few inches distance for the propeller to work from the transom. Both changes could possibly improve top boat speed performance. We await any new boat test speed results.